ドラえもん ありがとう ポスター

(税込) 送料込み

商品の説明

商品説明

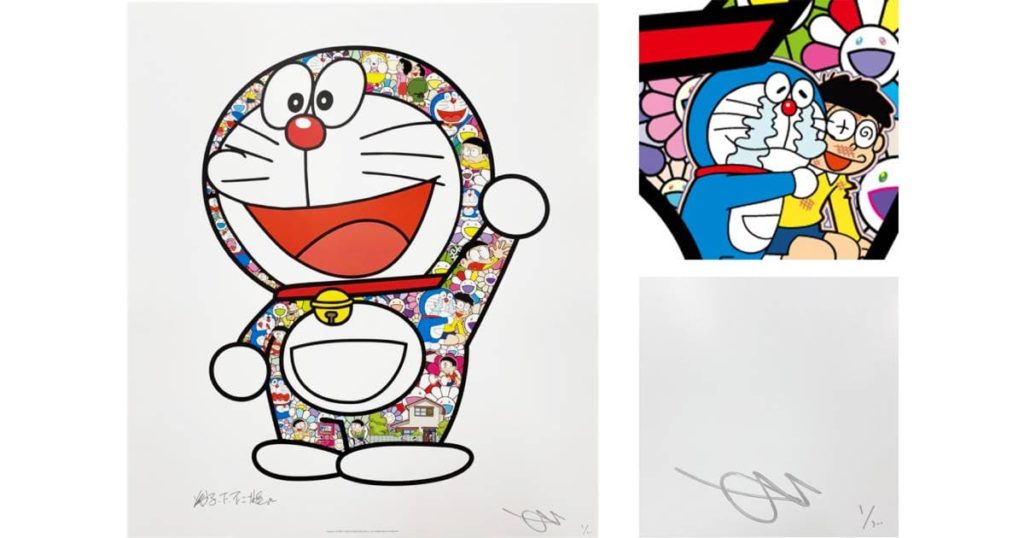

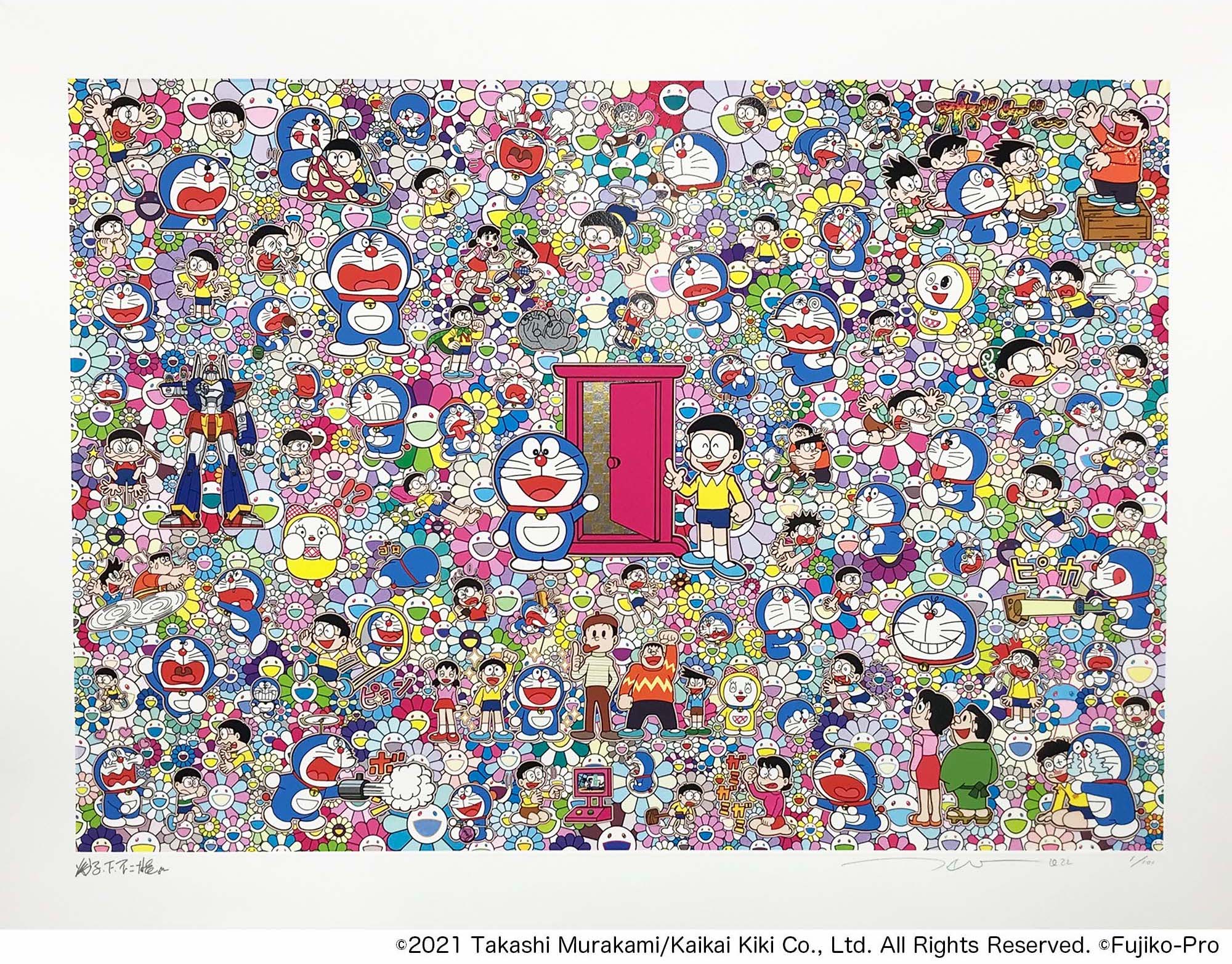

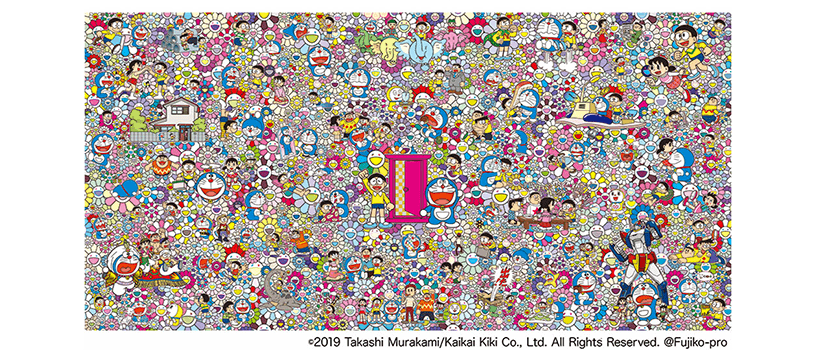

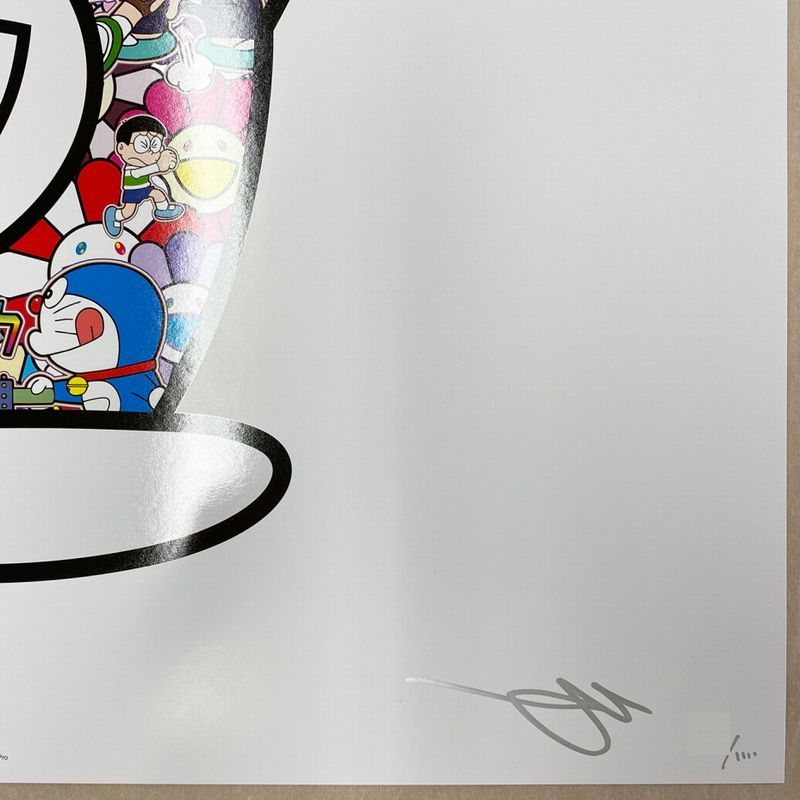

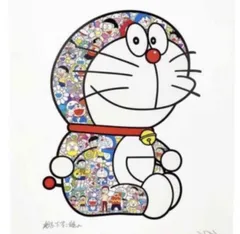

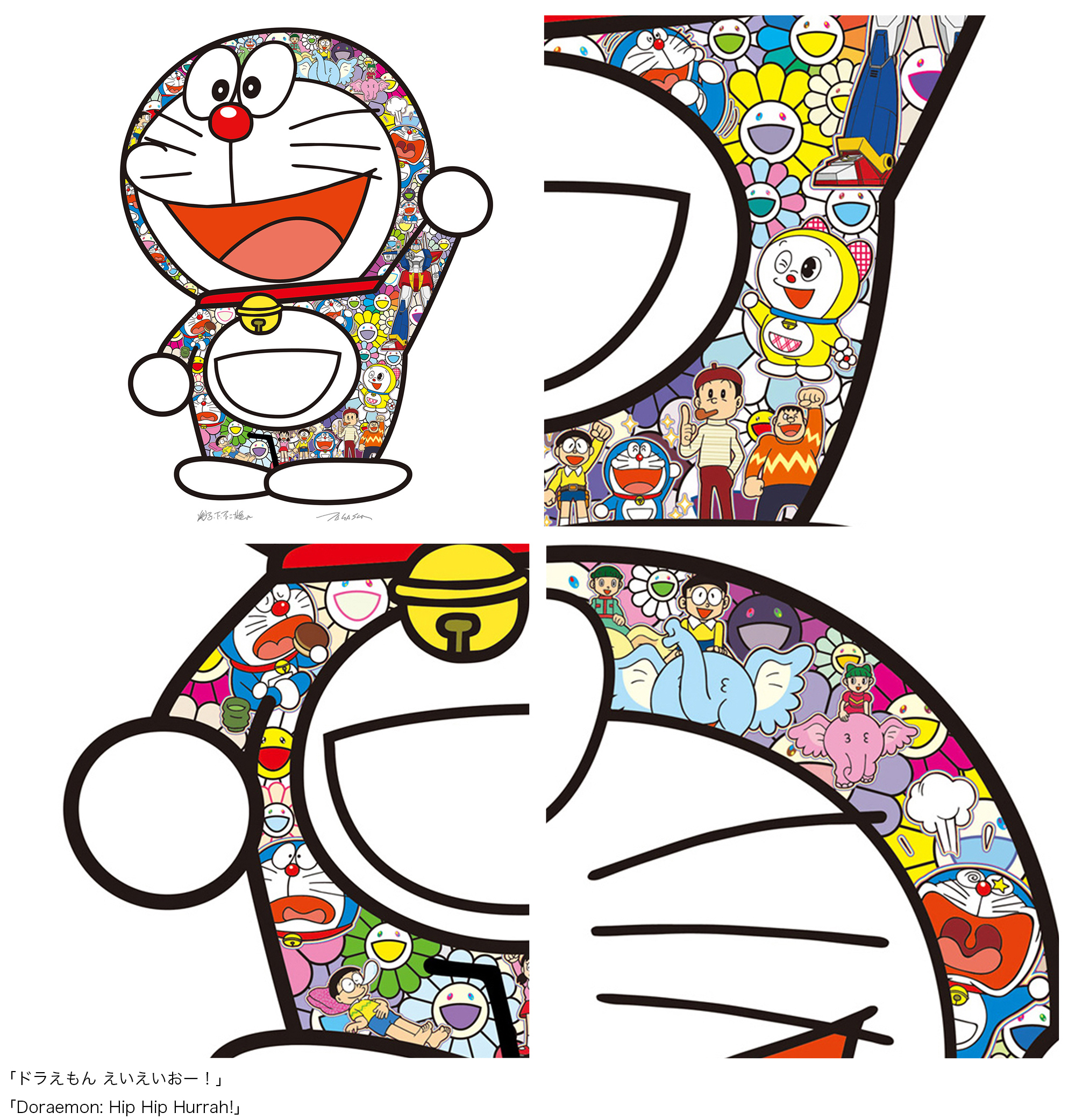

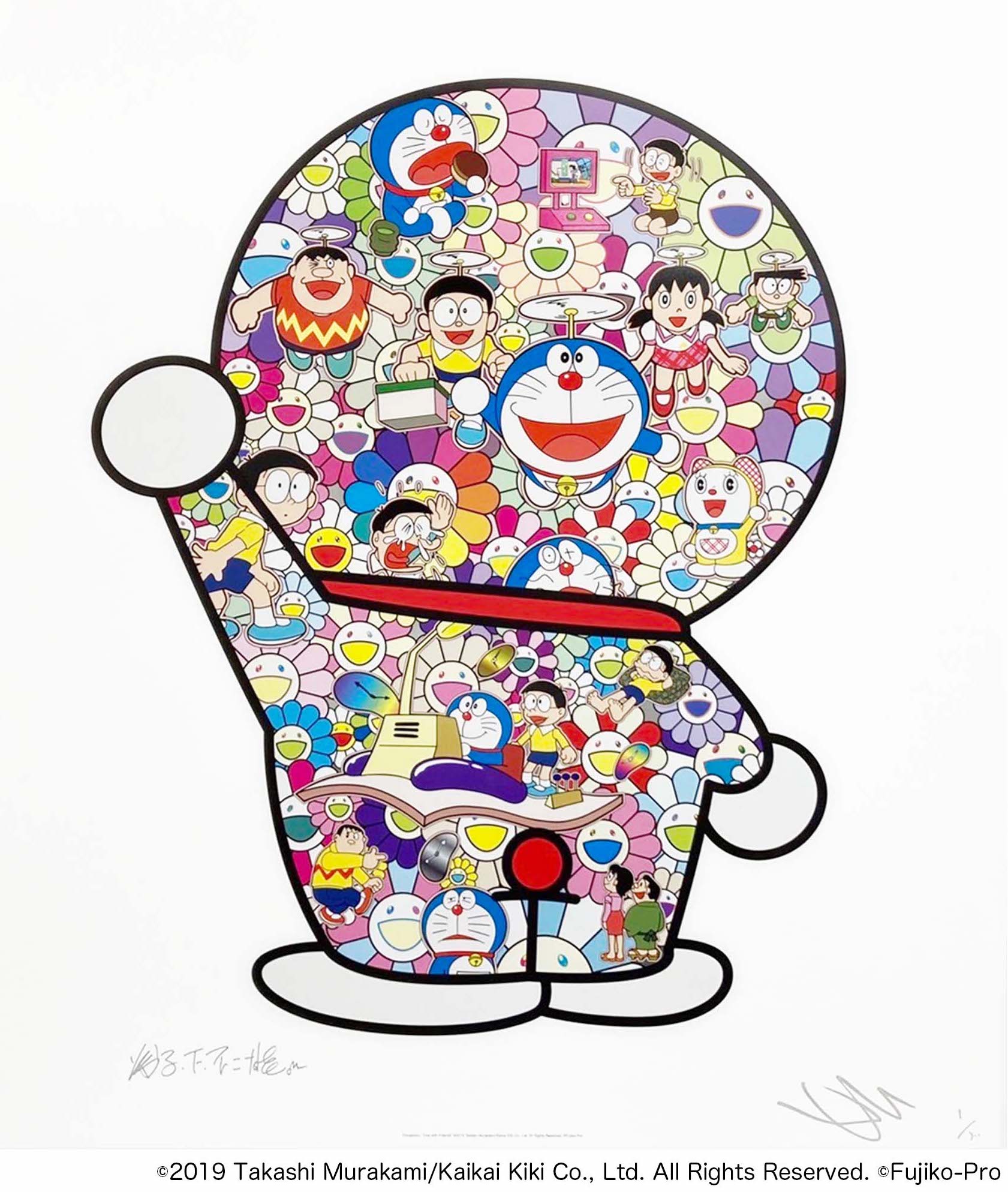

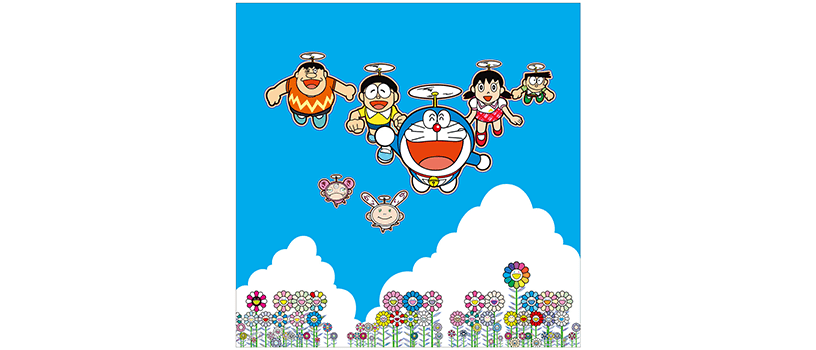

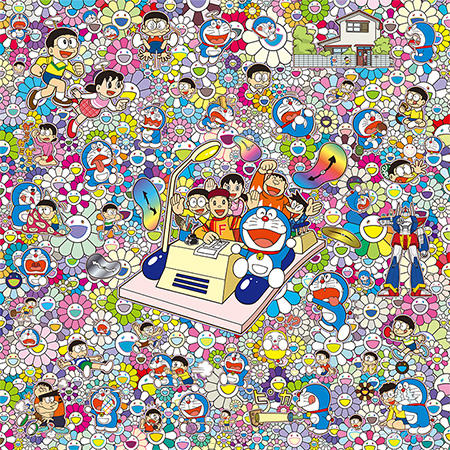

【作品詳細】ドラえもんありがとう

ポスター作品

ED:1000

Imagesize:537×422mm

Sheetsize:655×573.9mm

Offsetprint,withsilverandhighglossvarnishing

22200円ドラえもん ありがとう ポスターエンタメ/ホビー美術品/アンティークドラえもん ありがとう(ポスター作品)ドラえもん - ポスター版画ドラえもん ありがとう (ポスター作品) - dibrass.com

ドラえもん ありがとう ポスター 村上隆ポスター - everestgranite.ca

ドラえもん ありがとう(ポスター作品)ポスター - www.ecolet.bg

ドラえもん ありがとう(ポスター作品)ドラえもん - ポスター

ドラえもん 村上隆 ありがとう ポスター作品 Kaikaikiki - www

版画ドラえもん ありがとう ポスター - www.ecolet.bg

ポスター作品】ドラえもん ありがとう ポスター 直営 店 | alpron.co

ドラえもん ありがとう ポスター作品ドラえもん - キャラクターグッズ

ドラえもん ありがとう(ポスター作品)村上隆アニメグッズ - ポスター

日本入荷 ドラえもん ありがとう(ポスター作品) | artfive.co.jp

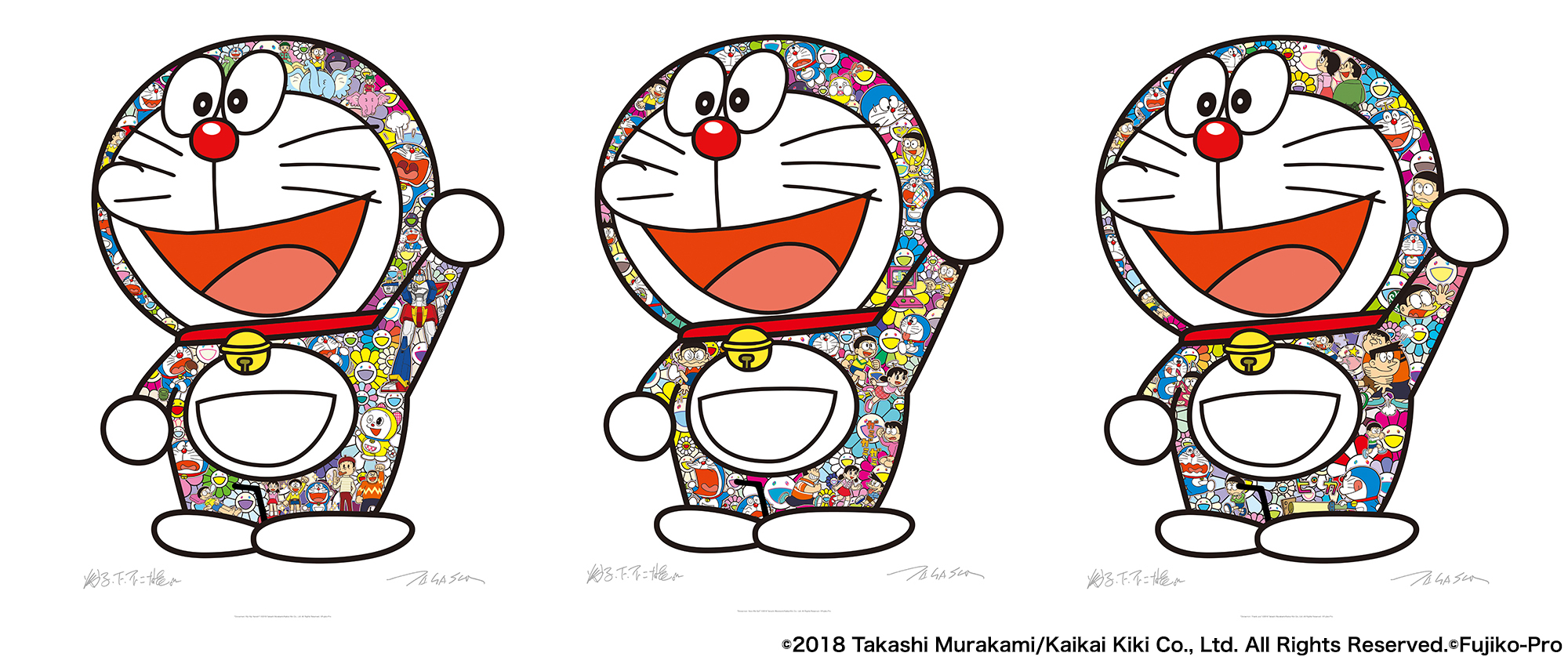

ドラえもん ポスター えいえいおー ありがとう さあ!いくぞ 村上隆 3

版画ドラえもん ありがとう (ポスター作品) - dibrass.com

その他ドラえもん ありがとう ポスター 村上隆 カイカイキキ - その他

公式オンライン 村上隆 ドラえもん ポスター ありがとう | artfive.co.jp

通販ストア 村上隆 ドラえもん ありがとう ポスター | www.butiuae.com

村上隆×ドラえもん「ドラえもん ありがとう」ポスター藤子F不二雄

ポスター村上隆 ドラえもん ありがとう - ポスター

お客様満足度NO.1 村上 隆 ドラえもん ありがとう ポスター - www

村上隆】 ドラえもん ありがとう ポスターポスター - benjaminstrategy.co

ドラえもん 村上隆 ありがとう ポスター作品 - pakalanainn.com

村上隆 カイカイキキ ドラえもん ありがとう [ポスター] カイカイキキ

村上隆ドラえもん ありがとう ポスター 村上隆 tonari no zingaro

ドラえもん ありがとう(ポスター作品)ゆず - cranetrain.pl

ドラえもん ありがとう ポスター 村上隆の+inforsante.fr

ドラえもん ありがとう ポスター - その他

655×5739mm村上隆xドラえもんコラボ ドラえもん ありがとう(ポスター

ドラえもん ありがとう ポスター作品 村上隆エンタメ/ホビー - ポスター

ドラえもん ありがとう (ポスター作品) - 絵画/タペストリー

ドラえもん ありがとう (ポスター作品)美術品/アンティーク - ecolet.bg

ドラえもん ありがとう ポスター 村上隆 - sorbillomenu.com

国内外の人気 ドラえもん ありがとう ポスター | yourmaximum.com

ドラえもん ありがとう (ポスター作品)美術品/アンティーク - ecolet.bg

ドラえもん ありがとう(ポスター作品)の+evergroup.com.pl

ドラえもん ありがとう (ポスター作品)美術品/アンティーク - ecolet.bg

ポスター作品】ドラえもん ありがとう-

655×5739mm村上隆xドラえもんコラボ ドラえもん ありがとう(ポスター

ドラえもん ありがとう(ポスター作品) 村上隆 売れ筋サイト - www

即決 送料無料 正規品 ドラえもん ありがとう 村上隆 ポスター サイン

2024年最新】ドラえもん ありがとう ポスターの人気アイテム - メルカリ

ポスター作品】ドラえもん ありがとうの+inforsante.fr

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています

![村上隆 カイカイキキ ドラえもん ありがとう [ポスター] カイカイキキ](https://static.mercdn.net/item/detail/orig/photos/m86899887101_2.jpg)